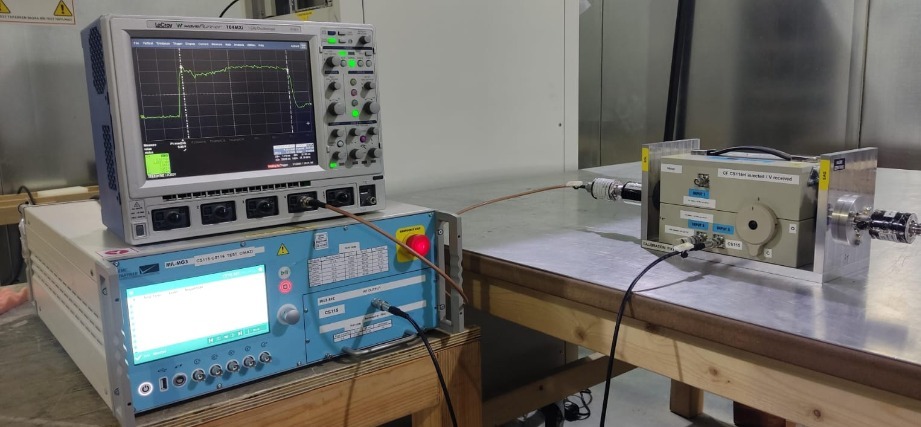

CS115 Test (Sensitivity Cable Injection Impact Through Conductivity)

MIL-STD-461 E/F/G

EMI/EMC Tests

CS115 Test (Susceptibility through Conductivity, Cable Injection, Impact), conducted within the scope of the MIL-STD-461 standard, is applied to the systems and subsystems of electrical, electronic and electromechanical devices designed for use in military systems, including power cables.

CS115 Test (Susceptibility to Conductivity, Cable Injection, Impact) requirements also apply to surface ship and submarine subsystems and suppliers of equipment for these systems. The CS115 Test (Susceptibility via Conductivity, Cable Injection, Pulse) method is applied by injecting pulses into cable bundles to measure the susceptibility of the tested device to pulse pulses to verify the ability of the cables connected to the equipment under test to withstand pulsed signals.

CS115 Test (Susceptibility through Conductivity, Cable Injection, Pulse) is performed by applying a square pulse with a width exceeding 30 nanoseconds and a repetition rate of 30Hz, with a rise and fall time of approximately 2 nanoseconds.

In addition, like other conductivity test methods, the CS115 Test (Conductivity, Cable Injection, Impact) can be used to test all land, naval and air force equipment, as well as ships, submarines, airplanes, military aircraft, navy aircraft, air force aircraft, launch It is applied to space systems equipment, including vehicles.

Within the scope of our STEST facility located in Ankara, which is an organization accredited by TURKAK, we conduct CS115 Test (Susceptibility through Conductivity) in the E/F/G versions of the MIL-STD-461 standard in accordance with the TS EN ISO/IEC 17025 General Requirements for the Competence of Testing and Calibration Laboratories Standard. , Cable Injection, Impact).

In order to increase the quality and reliability of your products, you can contact us for your Environmental, EMI/EMC and ATP Testing needs.

EMI/EMC Test Chambers Features

| Test Room 1 | Test Room 2 | Measurement unit | |

| Width | 6850 | 13000 | mm |

| Size | 5900 | 10000 | mm |

| Height | 3800 | 9000 | mm |

| Door Dimension | 1000x2000 | 4200x4750 | mm |

| Turntable Diameter | - | 6 | m |

| Turntable Load Carrying Capacity | - | 70 | ton |

| Reflection | Semi Anti-Reflective | Semi Anti-Reflective |

Standards

- MIL-STD-461E

- MIL-STD-461F

- MIL-STD-461G

CONTACT BY EMAIL

[email protected]

VOICE COMMUNICATION

+90 (312) 905 06 90

STANDART KONTROL VE TEST HİZMETLERİ A.Ş.