1What is EMI-Electromagnetic Interference?

EMI, Elektromanyetik Girişim anlamına gelmektedir. Tarihte yaşanan gelişmeler neticesinde zamanla frekans planlaması gereği ortaya çıkmıştır. Bu nedenle ilk olarak 1979 yılında Amerika Birleşik Devletleri’nde (ABD) Federal İletişim Kurulu (FCC) kurulmuş ve bu alanda çeşitli standartlar yayınlanmıştır. Elektromanyetik girişim, elektrik ve elektronik cihazların performansında azalma, bozulma ve hatalı işlenmesine yol açan radyo frekanslarına; doğal ya da beşerî her türlü bozucu etki veya işaret olarak tanımlanmaktadır. Bir cihazın elektromanyetik uyumlu olarak kabul edilmesi için 3 şart aranmaktadır:

• Kendi içinde girişime yol açmamak (Öz uyumluluk)

• Diğer cihazlara girişimde bulunmamak

• Diğer kaynaklardan girişime karşı etkilenmemek

Elektromanyetik girişim, cihazın etkilendiği elektromanyetik ortamın bir sonucu olarak gözlenir. Belirli bir bölgede meydana gelen tüm elektromanyetiksel olaylar, o bölgenin elektromanyetik ortamını oluştururlar. Oluşan bu elektromanyetik ortamın başlıca etkileri de EMI ve EMC olarak tanımlanabilir. Elektromanyetik çevreyi ise karakterize etmek istersek, 2 unsur karşımıza çıkar:

► Frekans / Zaman

► Genlik (Elektromanyetik enerjinin şiddeti veya gerilim-akım cinsinden değeri vb.)

Elektromanyetik girişimi oluşturan başlıca sebepler; kalitesiz kablolar, baskı devre elemanları, bağlantı noktalarındaki sızıntılar, dirençler, kondansatörler, indüktörler, eleman değişikliği, elektromekanik cihazlar, sayısal devre elemanları, mekanik anahtarlar şeklinde bir liste yapılabilir.

2What is EMC- Electromagnetic Compatibility?

Elektromanyetik uyumluluk ve girişim konusunda hem cihaz seviyesinde hem de platform ve sistem seviyesinde çeşitli testler mevcut. Bu testlerde kullanılan ölçütler de EMI-EMC standartları olarak belirlenmişlerdir. Elektromanyetik Girişim (EMI), Elektromanyetik Uyumluluğun (EMC) bulunmadığı durumlarda ortaya çıkar. Elektrikli ve elektronik cihazların çalışmaları esnasında çevreye standartlarca belirlenen limitlerin üstünde yayınımının olması veya bu yayınım karşısında olması gerekenden daha fazla alınganlık göstermesi, Elektromanyetik Girişim olarak değerlendirilebilir. Bu standartlar ürünün elektromanyetik olarak kalitesini belirleyen başlıca unsurlardır. Standartlarda iki önemli unsur yer alır:

► Test sınır değerleri.

► Test yöntemleri.

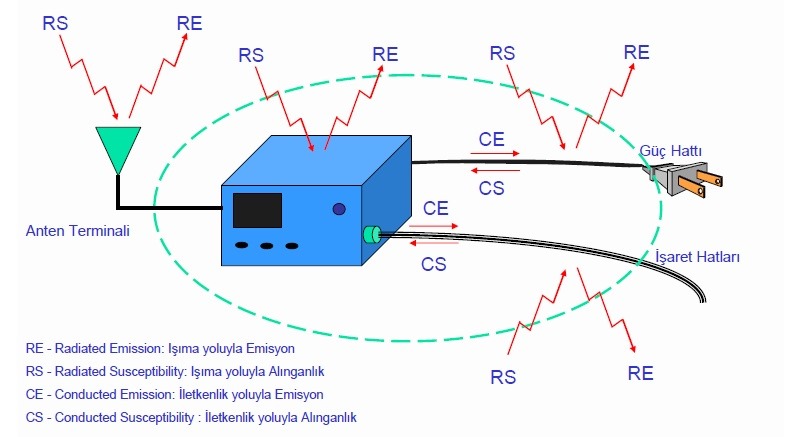

Askeri cihazlar için ayrı standartlar mevcut iken ticari cihazlar için de ayrı standartlar mevcuttur. EMI - EMC testinin iki yönü vardır:

► Emisyon

► Alınganlık ( Bağışıklık )

Emisyon testleri de 2 farklı yol ile yapılır. İlk olarak iletkenlik yoluyla yapılan emisyon testlerinde cihazın veya sistemin akım ve gerilim parametreleri ölçülür. Bu parametreler ölçülürken de akım probu ile akım, LISN (Line Impedance Stabilization Network- Hat Empedansı Sabitleyici Şebeke) ile de gerilim ölçülür.

Işıma yoluyla emisyon testlerinde ise elektrik alan ve manyetik alan ölçülür. Ölçüm yöntemi olarak da elektrik alan antenleri veya halka antenler kullanılır. Bikonik antenler (300-1000 MHz), Log - periyodik antenler ( 300 - 200 MHz) veya Horn antenler ( 1-18 GHz) de kullanılabilir. Tesisimizde tüm frekanslara uygun çeşitli antenler mevcut olup aktif olarak kullanılmaktadır.

EMI Alıcı kullanarak da tüm bu ölçümler çok daha kolay bir şekilde gerçekleştirilebilir. Bunun yanı sıra elektrik alan probu kullanarak da yüksek alanların ölçümü de sağlanabilmektedir.