EMI EMC TESTS

EMI / EMC Testing for Electrical and Electronic Equipment

As Standart Kontrol ve Test Hizmetleri A.Ş. (STEST), we perform EMI / EMC tests for electrical and electronic equipment in accordance with applicable national and international standards.

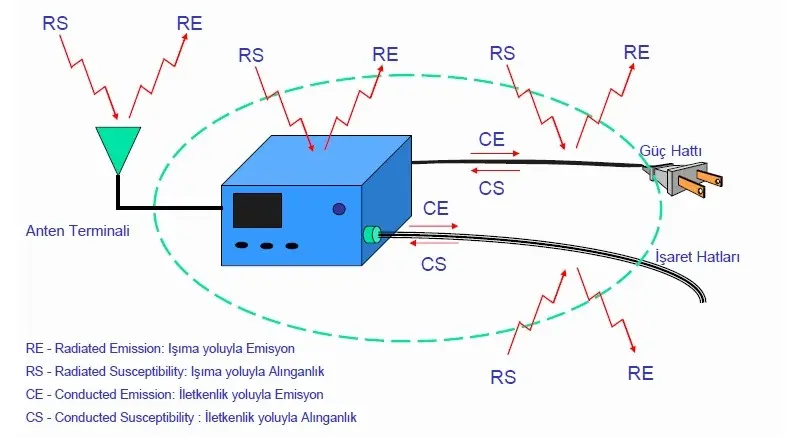

EMI (Electromagnetic Interference) refers to electromagnetic emissions generated during equipment operation that may adversely affect the performance of other devices. Such effects can lead to performance degradation, malfunction, and system failures. EMC (Electromagnetic Compatibility), on the other hand, is the capability of equipment to operate without disturbing its electromagnetic environment and to remain minimally affected by external electromagnetic phenomena.

What is EMI (Electromagnetic Interference)? Definition

- EMI is defined as electromagnetic emissions generated during the operation of electrical and electronic equipment that may adversely affect the performance of other devices.

- Such interference can result in performance degradation, malfunction, and system-level failures.

- To be considered electromagnetically compliant, equipment must be designed to avoid generating interference within its own subsystems.

- It is also expected to avoid interfering with other equipment and to demonstrate adequate immunity to external electromagnetic disturbances.

EMC and Our Testing Services Service

- EMC (Electromagnetic Compatibility) is the ability of equipment to operate without disrupting its electromagnetic environment and to remain minimally affected by external electromagnetic phenomena.

- Emissions Testing: Conducted emissions and radiated emissions, performed against applicable limits and methods.

- Immunity Testing: Performed based on the relevant EMI/EMC standards, limit values, and test procedures.

- Test Infrastructure: A shielded room and two semi-anechoic chambers.

- Measurements are performed across wide frequency ranges using biconical, log-periodic, and horn antennas; high-accuracy results are obtained with EMI receivers and E-field probes.

STEST supports risk reduction in the field by verifying standards compliance through EMI/EMC testing and by measuring both emissions and immunity performance of products and systems.

REQUEST A TEST APPOINTMENT

Our facility is equipped with three test chambers dedicated to EMI/EMC testing:

► Shielded Room

► Two Semi-Anechoic Chambers

► Control Room

The shielded room is an area isolated from external electromagnetic environments; the Faraday cage is the earliest and most prominent example of such isolation. A semi-anechoic chamber, on the other hand, is designed with electromagnetic wave-absorbing materials on its walls to minimize reflections.

Located in Ankara, STEST is a TÜRKAK-accredited organization. Within our facilities, we conduct EMI/EMC tests in compliance with TS EN ISO/IEC 17025 – General Requirements for the Competence of Testing and Calibration Laboratories.

To enhance the quality and reliability of your products, you may contact us for your Environmental, EMI/EMC, and ATP testing needs.