LOW PRESSURE TEST

TURKAK Accredited Testing and Verification

STEST is accredited by the Turkish Accreditation Institution (TURKAK) and carries out its testing and verification activities in an independent, competent, and impartial manner in compliance with national and international standards.

Low Pressure (Altitude) Test

The Altitude Test is performed to evaluate the performance and durability of products and systems when exposed to low air pressure at high-altitude conditions. This test is critical, particularly for the aerospace, defense and electronics industries.

Objective Target

- To verify the effects of low air pressure, temperature variations and oxygen levels on the product.

- To test sealing performance, structural integrity, cooling systems and functional operability.

Test Scope Scope

- High-altitude (low-pressure) simulations

- Rapid pressure changes (rapid climb/descent scenarios)

- Altitude + temperature combinations (low-temperature conditions at high altitude)

Technical Implementation Process

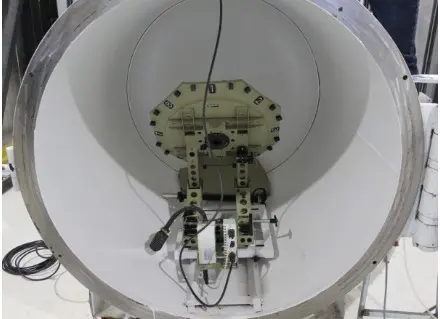

- During the Low Pressure / High Altitude Test, there must be absolutely no air exchange between the High Altitude Test Chamber and the external environment.

- For this reason, all interfaces of the test specimen (communication lines, power cables, etc.) are routed to the laboratory environment through hermetic feedthroughs via the chamber side ports.

- This enables functional testing to be performed safely and reliably throughout the test.

Application Areas Use

- Aircraft and helicopter components

- Electronic equipment

- Fuel systems and pressurized vessel systems

- Defense systems and munitions

STEST conducts low pressure / high altitude tests in accordance with MIL-STD-810 using advanced test chambers. Throughout the test program, your products are evaluated against international standards and comprehensive test reports are provided.

CREATE A TEST APPOINTMENT REQUEST