Icing and Freezing Rain Test

MIL-STD-810 F/G/H — RTCA DO 160 G

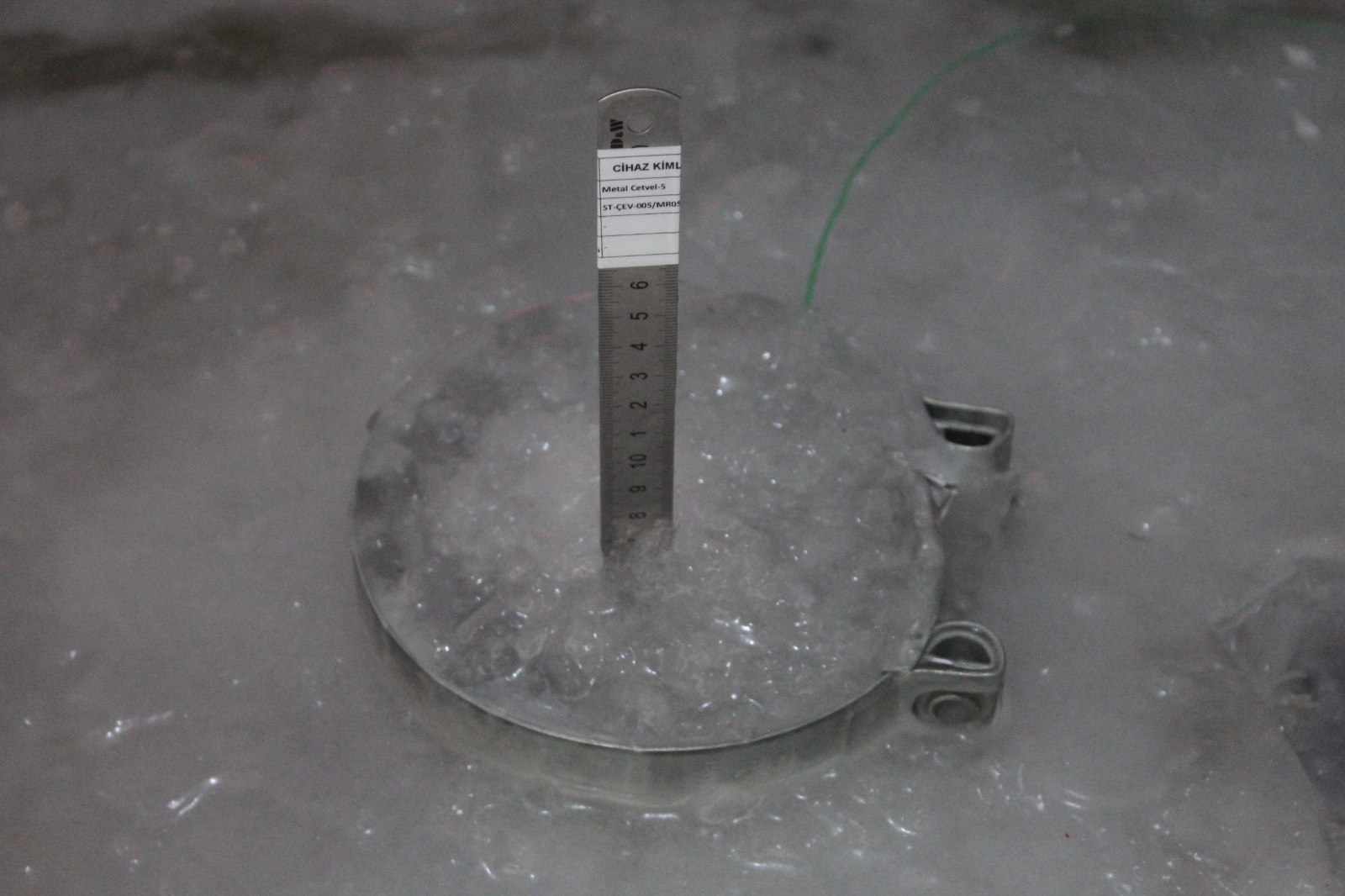

Icing and Freezing Rain Testing is critical to determine the durability of products under real-world conditions. This test is used specifically to detect potential problems caused by icing and develop solutions. The functional performance of the products is evaluated in detail by exposing the samples placed in the test cabin to the icing conditions that they may encounter in real use conditions.

During and after the Icing and Freezing Rain Test, the physical condition of the sample is meticulously examined and its functionality is checked. At this stage, detected errors are recorded and necessary correction steps are determined. The technical specifications of the icing and freezing cabinet are designed in accordance with military and civilian standards, which enables reliable tests to be carried out in various sectors.

Testing is performed according to MIL-STD 810 Method 521 standards to evaluate the effects of icing produced by freezing rain, fog or sea spray on the operating capacity of the equipment. This comprehensive method offers the opportunity to test the effectiveness of not only icing but also de-icing equipment and techniques.

In order to perform functional tests during the Icing and Freezing Rain Test, all interfaces of the sample, such as communication and power cables, can be removed to the laboratory environment from the side ports of the test cabinet. In this way, it can be measured more accurately how the product performs under real use conditions.

In addition to making your products strong against extreme weather conditions, these tests contribute to the process of finding solutions by identifying potential problems in advance. At STEST, we help you optimize the reliability of your products with icing and freezing rain tests.

Standards and Methods

- MIL-STD-810F Method 521.2

- MIL-STD-810G Method 521.3

- MIL-STD-810H Method 521.4

Enviromental Test Chamber Specifications

| Drive-In 1 | Drive-In 2 | Drive-In 3 | Drive-In 4 | Drive-In 5 | Drive-In 6 | Measurement unit | |

| Width | 6000 | 6000 | 9500 | 12000 | 15500 | 21500 | mm |

| Size | 4900 | 4900 | 4900 | 4900 | 4900 | 4900 | mm |

| Height | 4000 | 4000 | 4000 | 4000 | 4000 | 4000 | mm |

| Humidity Change Range | %20 RH ile %99 RH | %20 RH ile %99 RH | %20 RH ile %99 RH | %20 RH ile %99 RH | %20 RH ile %99 RH | %20 RH ile %99 RH | % |

| Temperature Change Rate | 3°C/minute (max) | 3°C/minute (max) | 3°C/minute (max) | 3°C/minute (max) | 3°C/minute (max) | 3°C/minute (max) | °C |

| Minimum Temperature | - 45 °C | - 45 °C | - 45 °C | - 45 °C | - 45 °C | - 45 °C | °C |

| Maximum Temperature | + 80 °C | + 80 °C | + 80 °C | + 80 °C | + 80 °C | + 80 °C | °C |

| Air Conditioning Chamber 1 | Air Conditioning Camber 2 | Measurement unit | |

| Width | 1000 | 2600 | mm |

| Size | 1000 | 2600 | mm |

| Height | 1000 | 2000 | mm |

| Humidity Change Range | %20 RH ile %99 RH | %20 RH ile %99 RH | % |

| Temperature Change Rate | 3°C/minute (max) | 3°C/minute (max) | °C |

| Minimum Temperature | - 76 °C | - 65 °C | °C |

| Maximum Temperature | + 150 °C | + 80 °C | °C |